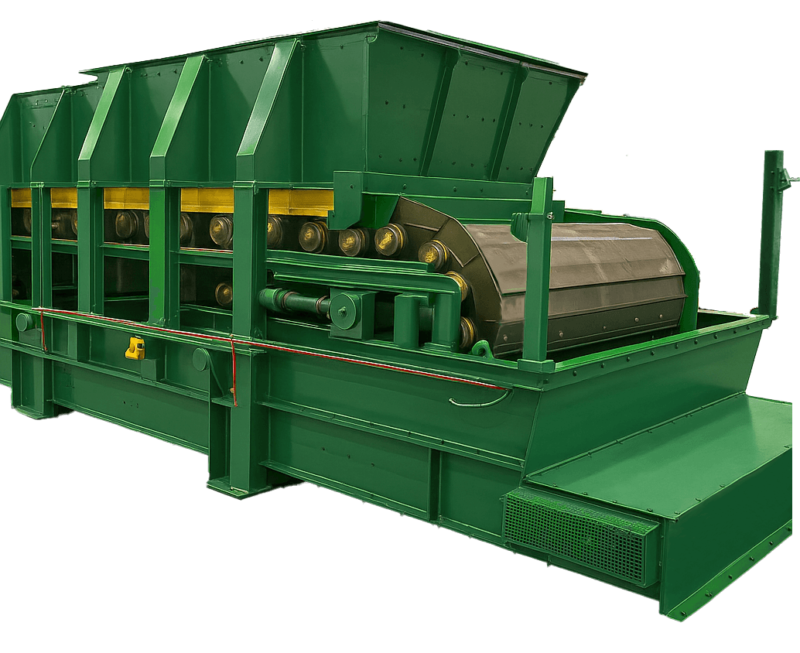

Apron Feeder

FMS Apron Feeders offer a wide range of applications for various feeding, unloading and discharging objectives. These Apron Feeders are particularly well adapted to provide solutions for the conveying of moist and sticky bulk materials, such as clay, gypsum, anhydrite and pozzolana among others, as the slightly arched plates of the Apron Feeder allow cohesive materials to be scraped off easily.

The conveyors are equipped with forged chains and wear-resistant components. The plate, chain and roller design is configured to suit the specific task and the required conveying capacity. The machines are completely assembled and test run on FMS premises, and transported as a pre-constructed unit to site for easy installation and fast commissioning

Functions and characteristics

Length up to 50 m

Tailor-made machines with a large range of sizes and parameters

Variable speed drive for metering

Apron Feeder Special options: Lump breaker

For breaking up and homogenisation of accumulated material (necessary for on-going weighing and metering)

Spillage conveyor for containment of fines can be designed as a scraper chain or as a belt conveyor

Integrated material guides ensure controlled material flow and accurate distance between the hopper structure and apron surface

Depending on material properties, guides are equipped with adequately wear-resistant linings

Control and automation unit for control of drive, coupling, lubrication and weighing systems

Impact beams which have polymer liners and automatic lubrication over their entire length

Apron Feeder for medium-duty applications

Options: spillage conveyor, lump breaker

Plate width up to 2,400 mm

Capacity up to 1,500 tph

FMS designed chains cover a wide range of capacities

Cost-effective solution for discharging of hoppers and stockpiles with medium-sized loads

With the addition of a weighing scale the unit can provide integrated discharging, weighing and metering

Crusher feeding

Unloading of multiple trucks at once

Intake of run-of-mine material directly from dump trucks

Each unit is tailor-made to suit the crusher

Material size up to 1,500 mm

Wagon unloading

Hopper discharge

Plate widths up to 3,000 mm activate the entire material column

Vertical or even negative angled walls for extremely sticky materials (e.g. clay)

No bridging or sticking on the walls

Special plate shape for better cleaning

Integrated metering and weighing is possible

Stockpile discharge

Several short feeders in series

Robust design

Reliable material extraction

Unlimited stockpile height

Apron Weigh Feeder

Combines material extraction from hopper with weighing and metering in one machine, for applications where use of a belt weigh feeder is not possible.

Suitable for high temperatures (up to 400°C)

Suitable for abrasive material

Plate widths up to 1,800 mm allow installation of the feeder under silos containing sticky material, and extraction of material in a wide flow

Various weight measuring solutions available, depending on material, structure, and how the material is received into the feeder (extraction from hopper, intake direct from tipper, etc.)

Full pre-assembly and calibration are carried out on FMS premises