Environment and Mineral Sustainability

Environment and Mineral Sustainability

Sustainability is connected to the issues responsible in terms of the environment, people and the economy. Here, we aim to be a trusted partner for our customers to have a sustainable productivity.

Based on company strategy we take care of following issues

Less footprint and environment friendly

Water saving

Energy saving

Health and safety for employees and people around the mine

Gender equality

Social responsibility

Recycling iron ore tailing

With the help of our wet high intensity magnetic separator (WHIMS), a recycling project is introduced in order to restore acceptable grade ores out of tail of the Chador Malu iron ore beneficiation plant.

Without any extra excavation and impact on environment, the processed ores are recycled into process line.

Innovation for green engineering

FMS R&D department provide solutions upon your challenges, including increasing efficiency and recovery, reducing dust, water and energy consumption and reducing the maintenance time.

To increase our competitiveness and make our planet a better place for future we take sustainability into account.

Sustainable productivity by Recovery+

With FMS recovery+ series of wet drum separators you can gain more product with the same water and energy consumption as conventional equipment.

Reduce wastewater and energy consumption

Sensor based sorting technology is implemented in beginning of AbbasAbad copper plant. This solution is provide to separate about 960 tons per day of low grade ores from entering to milling, screening and flotation and water treatment stages.

Greener mining by reducing CO2 emissions

FMS belt drum separator are designed to sort the raw large iron ores in early stages in mine.

This solution dramatically reduces material handling energy consumption. Returning 400mm crushed ore is much more eco-friendly mining behavior in comparison with returning wet and chemically processed concentrate tail.

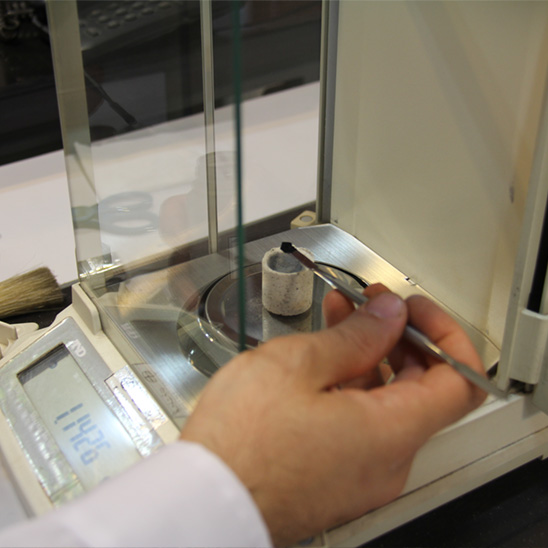

Sustainable plant maintenance by availability+ rolls

Our wear resistant coated rolls increase the mean time between replacements up to 5 times more than conventional stainless steel roll.

The AF190 roll are innovated for durable and high-quality performance of green pellet classifying process.

Protecting your pelletizing department equipment from tough tramp can be guaranteed via our scalper roller screen designed for sticky high humidity iron ore concentrate. SF80 makes such unique performance of scalper screen, while no roll replacement or re-gapping for 24 months.