Feeder

In general, a feeder is an equipment that feeds materials at a certain rate from a material storage source to the next stage. In industrial and mining plants, these equipment are able to feed materials with dimensions of 700 mm to 400 microns, and feeders are installed in the lowest part of the hopper or bin. The main task of this equipment is feeding and controlling its rate.

Feeder applications

Feeders are used to feed belt conveyors or other material handling equipment at a certain rate, feeders are intermediate between a storage source and a material handling system.

Application of feeder in different industries

Chemical and pharmaceutical industries

Mineral processing industries

Natural stone mines

Construction industry

Agriculture industry

Food industry

Conventional types:

Grizzly feeder

Apron feeder

Crank feeder

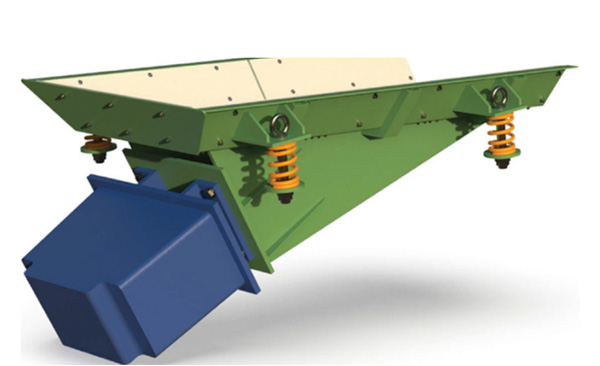

Vibrating feeder

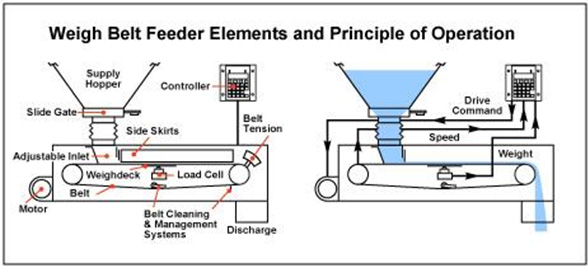

Belt feeder

Feeder driving force is divided into two parts depending on the type of mineral, capacity and process stage

Electromagnetic

Electromagnetic feeders are usually used for feeding and dosing. Magnetic drives are capable of continuous manual adjustments during operation. They can reach full power quickly after being turned on. For a precise dosing operation, when the equipment is turned off, the feeder immediately cuts off the material flow in a fraction of a second.

Unbalance motor

Unbalanced motor feeders are complete and economic feeders with low maintenance costs. Based on the project conditions, the client may need to design a special feeder. For example, due to the lack of sufficient space, a 2750×2750 feeder is designed to spread the material uniformly on the magnetic drum separator.

FMS, with more than 30 years of experience in designing, manufacturing, installing and operating mineral processing equipment, is able to design and manufacture all kinds of feeders in different dimensions for mining industries.